How the Fasterblaster clean the inner and outer steel tube?

New Concrete Surface Preparation Shotblasting Cleaning Machine Rovan

September 29, 2020

What’s the structure of tank shot blasting machine ? How to rationally use tank shot blasting machine?

October 13, 2020Fasterblaster has a very high efficiency in cleaning steel tubes as a new shot blasting machine. The radian surface is designed to cover the steel tubes in a full range, remove the adhesive sand, rust layer, welding slag, oxide skin and sundries, One-time shot blasting surface is enough to prevent secondary rework and save time cost.

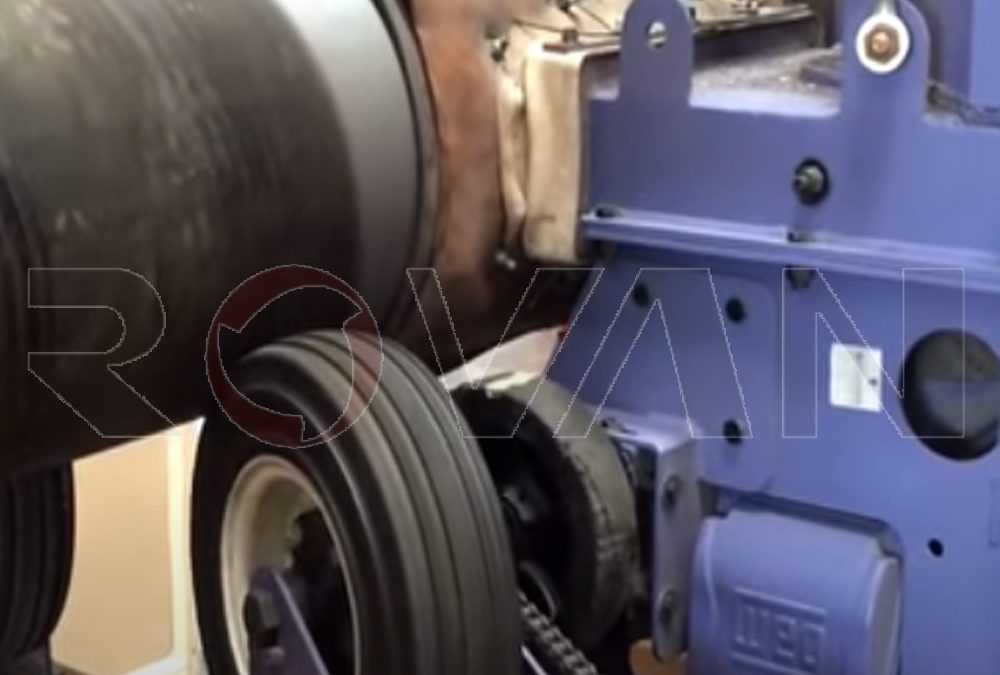

The Fasterblaster equipment design is reasonable and smooth, including the placement of shot blasting device and shot blasting Angle, etc. To give it a fine, smooth surface. There is no dead Angle in the operation process, the shot blasting time is faster than the old drum equipment, the effect is also very prominent to achieve the purpose of complete cleaning.

After cleaning, the steel pipe has a silver-white metallic luster, with obvious dust removal effect and no pollution to the environment.

It is suitable for cleaning the inner and outer walls of steel tubes and products. No manual feeding is required, and the inner and outer walls of various diameter steel tubes have good performance. A Fasterblaster remote control device can control the whole process of blasting cleaning.

During Fasterblaster shot blasting, the speed is uniform and stable, which can effectively reduce the failure rate of equipment components and improve the quality of casting.